The Structural and Civil group is another particular strength of MMC O&G and has earned an excellent reputation for expertise, efficiency and innovation in structural design. Our experience in designing and optimizing offshore structures and platform is of particular note.

Our team of professional engineers, designers and draughts persons has expertise and experience in a wide variety of projects for many major projects in Malaysia and overseas, including onshore and offshore petrochemical, oil and gas and processing facilities.

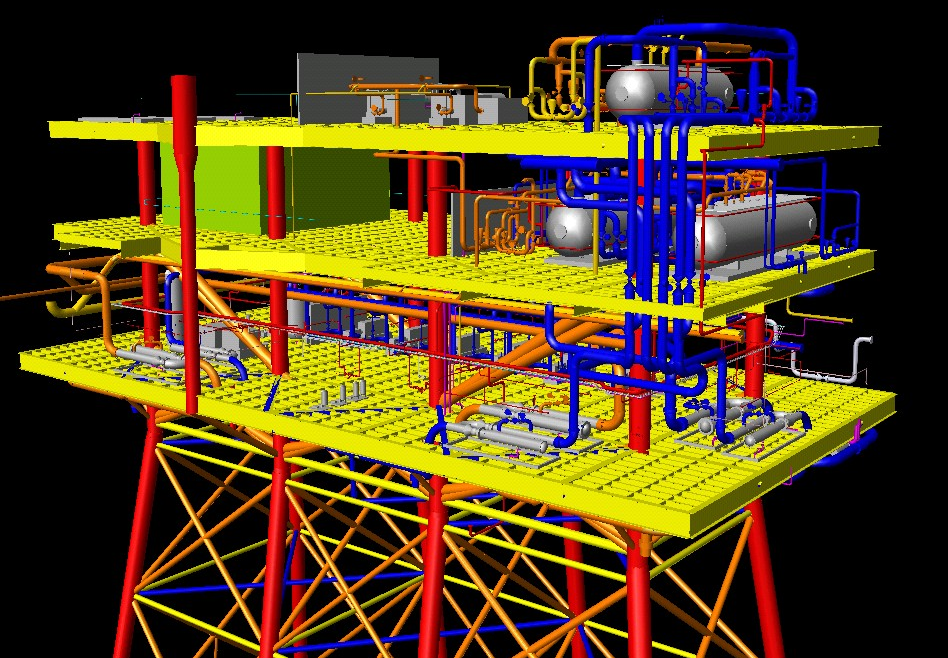

MMC O&G has carried out the structural design and detailing of facilities for offshore platforms and onshore production plants, including support structures, conveyers, pipeways, vessel supports, access platforms, and buildings.

The Structural and Civil group is another particular strength of MMC O&G and has earned an excellent reputation for expertise, efficiency and innovation in structural design. Our experience in designing and optimizing offshore structures and platform is of particular note.

Our team of professional engineers, designers and draughts persons has expertise and experience in a wide variety of projects for many major projects in Malaysia and overseas, including onshore and offshore petrochemical, oil and gas and processing facilities.

MMC O&G has carried out the structural design and detailing of facilities for offshore platforms and onshore production plants, including support structures, conveyers, pipeways, vessel supports, access platforms, and buildings.

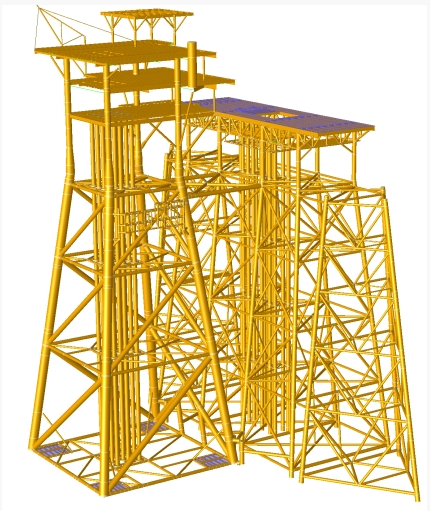

For offshore design MMC O&G is capable of topside, jacket/tripod, vent/flare boom, bridge, living quarters, telecom tower and helideck. The jacket design covers all stages of its life cycle which include in place analysis, dynamic analysis, dynamic spectral fatigue or deterministic fatigue, loadout, dynamic launch, lifting, flotation and upending, on bottom stability, boat impact, pile and conductor drivability, mooring, non-linear collapse, platform abandonment, detailed finite element analysis on critical connections, barge motion, transportation, mudmat, wave slamming, vortex shedding, boat landing, riser guard, and other miscellaneous analyses.

The group makes use of state-of-the art computer technology and software programs like SACS, SESAM, STAAD-3, GRLWEAP, and ISAAC/MOSES for design and analysis work. We also have capability to carry out 3D structural design by using BOCAD. The combination of these design programs with our in-house CAD capability ensures that efficient and effective solutions to structural problems are provided.

SACS, which was developed by Engineering Dynamics, Inc based in New Orleans, USA, is well known for its structural analysis capability and is widely used in the local and overseas oil and gas industry. The software is capable of handling all the analysis work for offshore structure and is very user friendly. SACS has the capability to do code check as per most of the codes including API-LRFD and API-WSD.

For the non-linear pushover analysis, which includes the boat impact analysis and the pushover analysis, the COLLAPSE module in the SACS suite of programs is utilized. The COLLAPSE module can simulate both the material and geometric non-linearity. Member elastic and plastic buckling are automatically calculated for using the member deflected shape and the plasticity of the member sub-segments. Local tubular buckling is determined using LRFD procedures and treated as hinges in the analysis.

The analysis capabilities are supplemented with GRL-WEAP for the pile drive-ability analysis and with ISAAC/MOSES for the motion and mooring analysis. For onshore design work, STAAD-3 is utilized to cater for both steel and concrete design. SESAM is used as an alternative to SACS depending on the client’s preference. For detailed finite element analysis, SACS or SESAM is capable of doing both linear and non-linear simulation. Both software’s have an extensive library of elements for modeling purposes.